ECO BRASS® Is the Solution to Avoid Dezincification of Brass Components

Brass is a broad term for alloys of copper and zinc, and it’s used to make many useful things, from keys to plumbing fittings. It is not often that those using the final product know the composition of their brass parts, but now, with some substandard brass in the marketplace, it is important to know your source. Brass has long been known as the go-to metal for plumbing and still is. However, our growing global commerce has made it essential that the plumbing parts that are sourced are sourced from good high quality brass, such as ECO BRASS®. Notably, dezincification has been an issue that has brought the composition of brass components into the conversation when purchasing brass parts.

ECO BRASS® high performance silicon brass is lead-free, has excellent machinability, forgeability, and high strength equivalent to stainless steel, while eliminating the problems of stress corrosion cracking and dezincification.

There are many compositions of brass with some being more appropriate in certain applications.

What is brass?

- It is an alloy of copper and ≥5% zinc (the highest volume brass rod alloy contains ~35% zinc)

- It can contain optional performance enhancing elements (to improve machinability, corrosion resistance, etc.)

- It contains residual elements (from the materials melted to make new brass) which can be neutral or harmful to corrosion performance

- It is a versatile alloy that can be cast, wrought or forged

Standard machining brass (C360000) is comprised of about 61 percent copper, about 35 percent zinc and 2.7% lead but there are other types of brass that are used for plumbing pipes, which have varying amounts of zinc and copper.

What is dezincification?

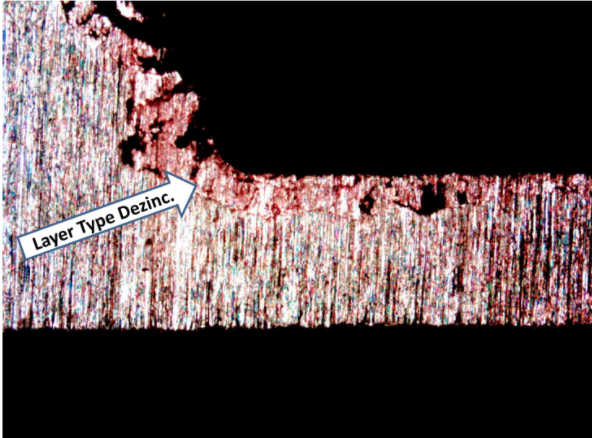

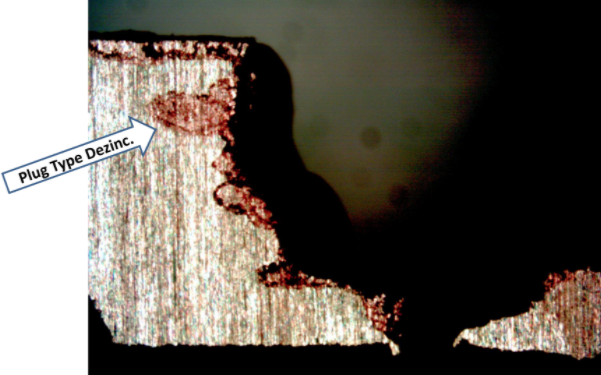

Dezincification is a type of corrosion where the zinc is leached out of the brass. The table below shows the water conditions that can cause dezincification and the pictures below the table show the two types of problems it causes.

| Water Conditions | Dezincification Type |

| High O2 & CO2 , stagnant or slow moving water | Layer – Progression is slow & along a broad front. |

| Slightly acid water & low salt content | Layer – Progression is slow & along a broad front. |

| Soft water, low pH, low mineral content | Layer – Progression is slow & along a broad front. |

| Waters high in chloride ions | Layer – Progression is slow & along a broad front. |

| Neutral / alkaline waters, high salt, ≥ room temperature | Plug – Progression is faster and localized. |

The problem with dezincification is that you can’t always see it because most of the time it’s happening on the inside of the part. Once the zinc has been leached from the brass, the component becomes porous, brittle, and prone to failure, and the likelihood of brass failure can increase with the amount of zinc in the alloy. In addition to the composition (examples are shown below), there are other factors that contribute to dezincification such as poor manufacturing controls that affect the microstructure or poor control of residual elements. In addition, poor control of copper and zinc that result in higher than specification zinc contents can be an problematic. Essentially, lack of consistent controlled manufacturing can be an issue. For this reason, it’s important to understand the different types of brass alloys and their compositions as they relate to plumbing parts.

High Zinc Content – Should not be used for plumbing. ECO BRASS® is the solution that dismisses all of these issues. ECO BRASS® is sourced from an American made foundry that honors the composition of brass needed for effective parts.

Here are some of the brass compositions available in the marketplace:

- C27450 – LOW LEAD – 60 to 65 percent copper, about 38 percent zinc, and a maximum of 0.25 percent lead

- C36000 – STANDARD – 60 to 63 percent copper, about 36 percent zinc , and 2.5 to 3 percent lead

- C36300 – LOW LEAD – 61 to 63 percent copper, 38 percent zinc maximum, 0.25 to 0.7 percent lead, and 0.04 to 0.15 percent phosphorus

- C37000 – LOW LEAD – 59 to 62 percent copper, about 39 percent zinc, and 0.8 to 1.5 percent lead

Lower Zinc Content – Should be used for plumbing

- C87850 – ECO BRONZE® – 75 to 78 percent copper, about 21 percent zinc, 2.7 to 3.4 percent silicon, 0.05 to 0.20 percent phosphorus and a maximum of 0.09 percent lead

- C69300 – ECO BRASS® – 73 to 77 percent copper, about 21 percent zinc, 2.7 to 3.4 percent silicon, 0.04 to 0.15 percent phosphorus and a maximum of 0.09 percent lead

Brass is the ideal material for long term plumbing solutions.

Brass is lauded for its resistance to corrosion. For this reason, it’s considered extremely durable and long-lasting. When working with potable water, ECO BRASS® is the solution. As we are discovering, the composition of the brass matters. For example, brass plumbing pipes tend to have an expected lifespan of between 40 and 70 years. When brass starts to experience dezincification, red spots may become visible on the fitting or pipe. When brass fittings and plumbing pipes lose their zinc, it results in leaks and/or complete pipe blowouts. Unfortunately, dezincification isn’t often apparent until leaks occur.

When the marketplace experiences water issues caused by dezincification, the users tend to move away from brass components entirely. In order to preserve brass’s market penetration in the residential water market, American-made ECO BRASS® or ECO BRONZE® should be used. The type of brass is an important, yet overlooked, part of the plumbing solution. With the right source of brass, the components will again enjoy a 40-70 year part lifespan.

How to react to issues caused by dezincification.

Dezincification occurs over a period of time. For this reason, it’s important to maintain vigilance and look for the common signs of dezincification, which include red spots on brass pipes and fittings, water leaks and cracks in the brass plumbing pipes. Since many plumbing pipes are located behind walls, it’s important to pay attention to low water pressure and abnormally high water bills, which could indicate leaks in the system. Additional signs of water leaks include mold, musty odors and water spots on walls and ceilings.

Once these issues are noticed, it’s important to replace the failed plumbing components. While it may be tempting to replace them with the same type of brass, it will be better to choose a different American-Made ECO BRASS® or ECO BRONZE® for these fittings. Knowing the source will help to ensure the quality of the component.

How to prevent dezincification?

Preventing dezincification starts with understanding the operating conditions for your brass plumbing pipes and fittings. If you plan on using brass for your plumbing system, it’s important to source from a high-quality reputable manufacturer.

It can be tested:

Created in 1981, ISO 6509 has been used because it is a short term test that is simple to run but has correlated with long-term performance in the field (see footnote 1). As you can see, it is the basis for the other tests in the table.

| ISO 6509 ²⁺³ | AS2345 | UL199 | EN12164 | |

| Application | General | General | Sprinklers | Rod |

| Test Solution | 1% CuCl₂ | 1% CuCl₂ | 1% CuCl₂ | 1% CuC₂ |

| Test Temperature | 75⁰ C | 75⁰ C | 75⁰ C | 75⁰ C |

| Test Length | 24 Hr. | 24 Hr. | 144 Hr. | 24 Hr. |

| Max. Dezinc. Depth Avg. Dezinc. Depth | See note 3 | – L:300µ; T:100µ |

200µ | 200µ

100µ |

(1) Initially developed to correlate with Swedish, Australian, and South African field tests.

(2) Example of user defined pass/fail criteria: NSF/ANSI 14 limit is 200µ

(3) ISO6509-2 was approved on 3/6/2017 for the following limits:

- forgings & castings avg. 100µ, max. 200µ;

- extruded rod longitudinal avg. 300µ, max 400µ and transverse avg. 100µ and max 200µ.

Find the right source

In order to maximize the useful lives of your brass fittings, it’s important to select the correct American-made ECO BRASS® or ECO BRONZE® for your plumbing system and not try to save money by ordering cheap brass from overseas.

ECO BRASS® is the solution. Dynamic, ECO BRASS® is corrosion resistant; strong, equivalent to steel, does not get brittle at high temperatures and green, lead-free, arsenic-free, bismuth-free, NSF/ANSI/CAN 61 Compliant, bismuth-free, and NSF/ANSI/CAN 61 Compliant.